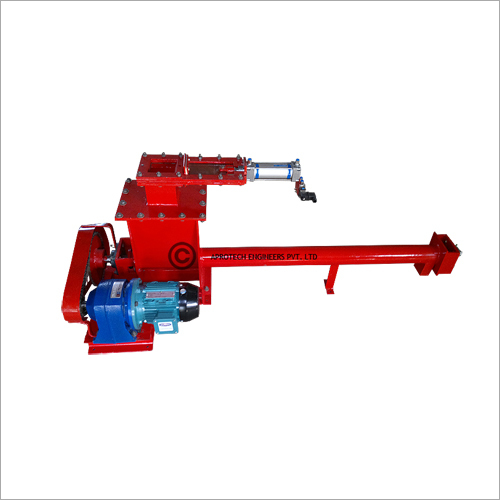

Screw conveyor

Screw conveyor Specification

- Rotation Type

- Horizontal or Inclined

- Control System

- PLC controlled / Manual

- Motor Type

- Three Phase Induction Motor

- Belt Type

- Screw (helical blade)

- Lifting Speed

- Variable, up to 60 m/min

- Equipment Type

- Screw Conveyor

- Features

- Dust-proof, Enclosed Structure

- Condition

- New

- Lifting Capacity

- 0.5 - 10 Tons (customizable)

- Max. Lifting Load

- Upto 10 tons

- Max. Lifting Height

- Upto 60 feet

- Power Source

- Electric

- Power Consumption

- 1-15 kW (depending on size)

- Voltage

- 220-415 V

- Length of Belt

- As per requirement (customizable)

- Feature

- Automatic Operation

- Attributes

- High durability, Corrosion resistance

- Temperature Range

- -10°C to +70°C

- Noise Level

- Low

- Lubrication

- Automatic/Manual

- Material of Construction

- Mild Steel / Stainless Steel

- Application

- Cement, Food, Chemical, Agro Industries

- Surface Treatment

- Painted / Powder Coated

- Hopper Type

- Available as Open/Closed

- Operation Mode

- Continuous

- Discharge Height

- Custom as per requirement

- Screw Diameter

- 100 mm to 800 mm (customizable)

- Conveying Capacity

- Up to 100 TPH

- Mounting Type

- Floor mounted, Inclined, or Vertical

Screw conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1-3 Days

- Main Domestic Market

- All India

About Screw conveyor

We are recognized as a profound manufacturer and supplier of Volumetric Screw Feeder due to our consistent quality delivery in our products range. We offer different varieties in our screw feeders on account of their capacities, qualities and other dimensions to meet with the demands of our highly reputed clients. We engineer these screw feeders by using premium quality raw materials and latest technologies as per the set guidelines of industrial quality standards. Our screw feeders are widely demanded due to their unmatched attributes like robust & precise construction, high end performance and low operational & maintenance cost. Our offered Volumetric Screw Feeder is widely used in various industries for numerous applications like engineering pre-processing, cement kilns, fuel cartridge systems and gasifiers.

Versatile Material Handling Solutions

Tailored to your operational demands, our screw conveyors operate efficiently in horizontal, inclined, or vertical configurations. They can be customized for various capacities, screw diameters, and lifting heights, ensuring smooth and reliable handling of bulk materials with minimal downtime.

Engineered for Performance and Durability

Constructed from high-quality mild or stainless steel, these screw conveyors are built to withstand challenging environments. Their dust-proof and enclosed design offers corrosion resistance and safety, while surface treatments like powder coating further enhance longevity in demanding industrial settings.

User-Friendly Operation and Control

Thanks to intelligent PLC or manual control systems, adjusting conveyor speed and performance is straightforward. Automatic and manual lubrication options reduce maintenance intervals. Users benefit from smooth, continuous operation supported by reliable three-phase induction motors and flexible power voltage compatibility.

FAQs of Screw conveyor:

Q: How does the screw conveyor adapt to different materials and industries?

A: The screw conveyor is available in both mild steel and stainless steel constructions, accommodating a broad range of materials such as cement, food products, chemicals, and agricultural goods. Customizable screw diameters and lengths allow it to be tailored for the specific density and flow needs of each industry.Q: What surface treatments are offered and how do they benefit the equipment?

A: Surface treatment options include painted and powder-coated finishes, which provide robust corrosion resistance and extend the service life of the conveyor, especially under harsh industrial conditions commonly found in cement and chemical processing environments.Q: When should I choose an inclined or vertical screw conveyor configuration?

A: Inclined or vertical mounting is recommended when materials need to be lifted to higher elevations or transferred across multiple levels within a facility. These configurations are ideal for maximizing space and efficiently transporting materials up to 60 feet, with variable speed control for precise handling.Q: Where can the screw conveyor be installed for effective operation?

A: The conveyor is engineered to support floor-mounted, inclined, or vertical installations, making it suitable for integration into existing production lines in factories, processing plants, or storage facilities. Custom discharge heights ensure compatibility with your specific site layout.Q: What process steps does the conveyor support in automated operations?

A: The screw conveyor operates continuously, driven by a three-phase induction motor with PLC-controlled or manual modes. It maintains automatic or manual lubrication, consistent material flow, and precise speed adjustment, ensuring efficient and low-noise operation throughout the conveying process.Q: How is the equipment maintained and what is its expected lifespan?

A: Maintenance is simplified with automatic or manual lubrication systems and robust design. With proper care and periodic checks, the corrosion-resistant build and durable components contribute to a long operational lifespan, even under high-duty cycles.

Price 300000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1-3 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+